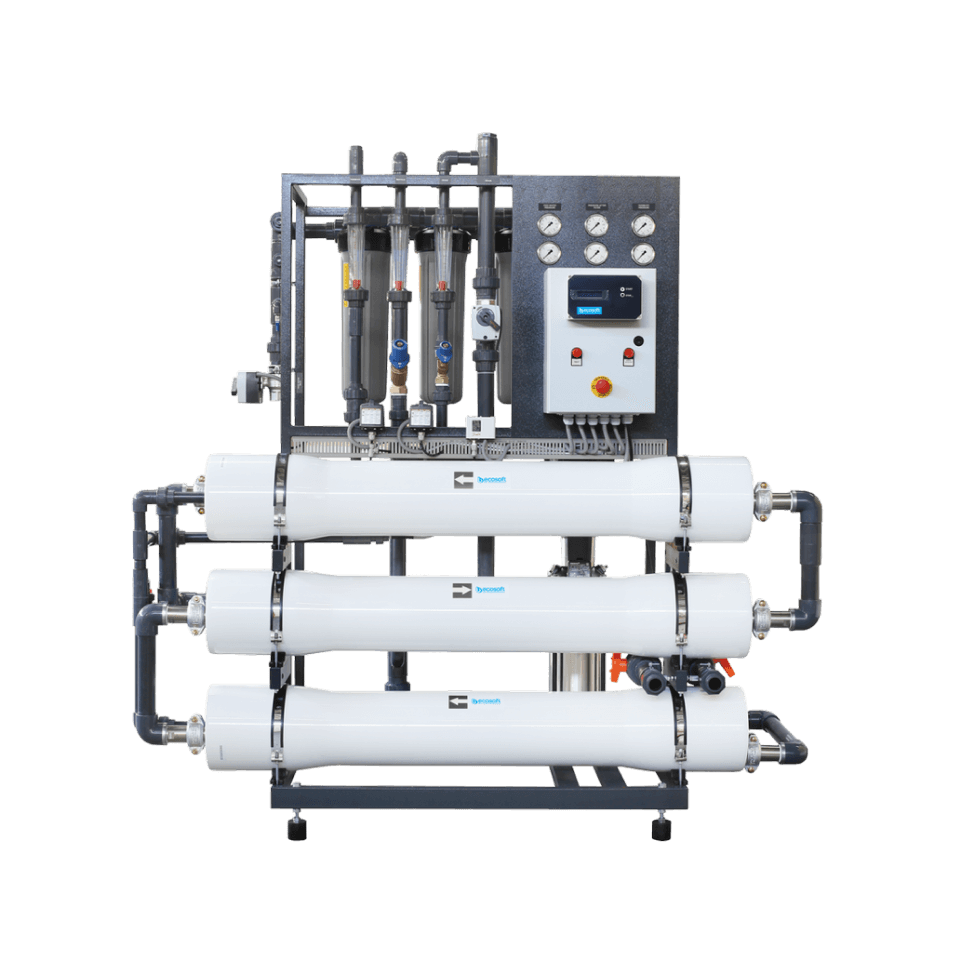

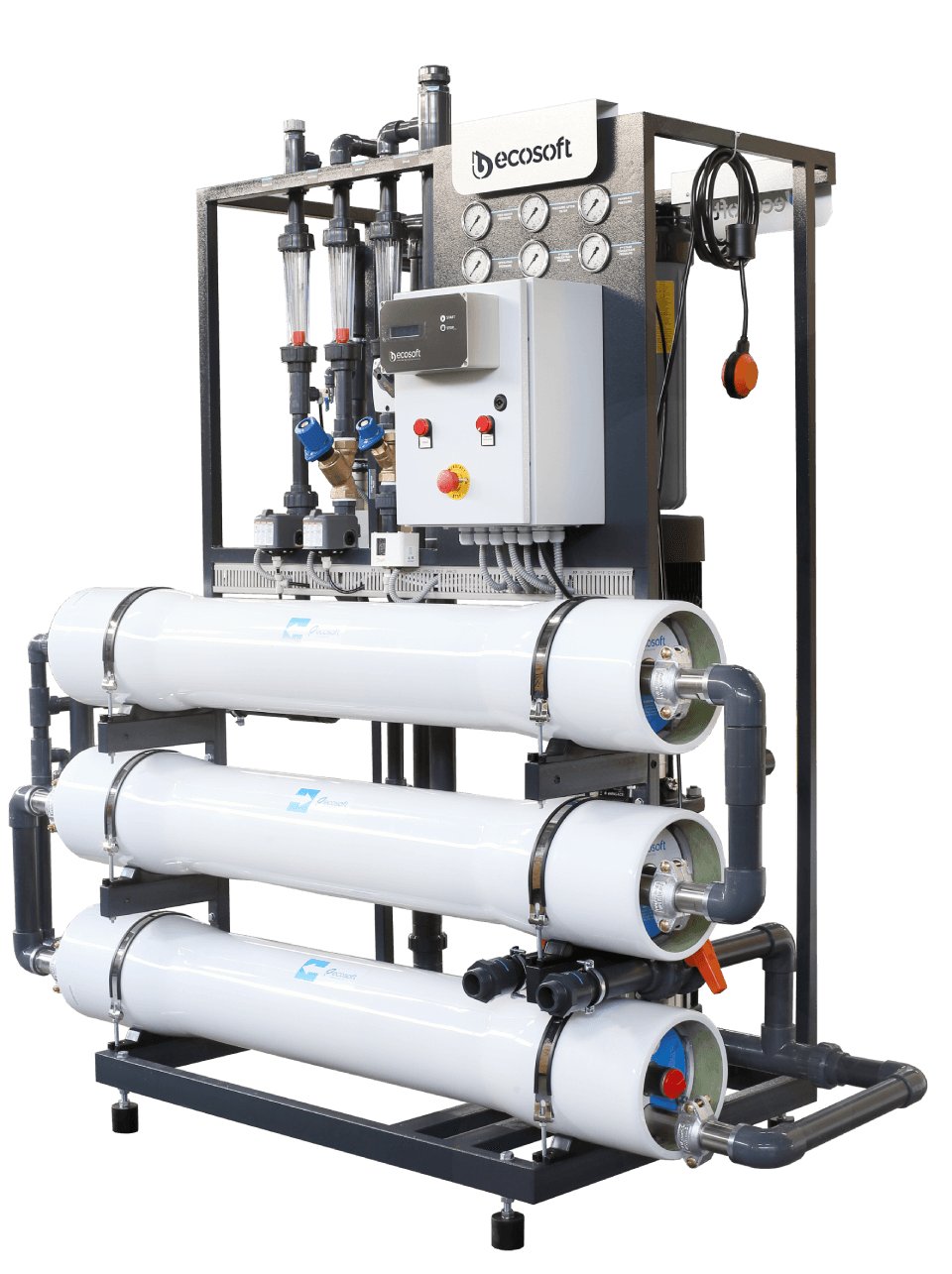

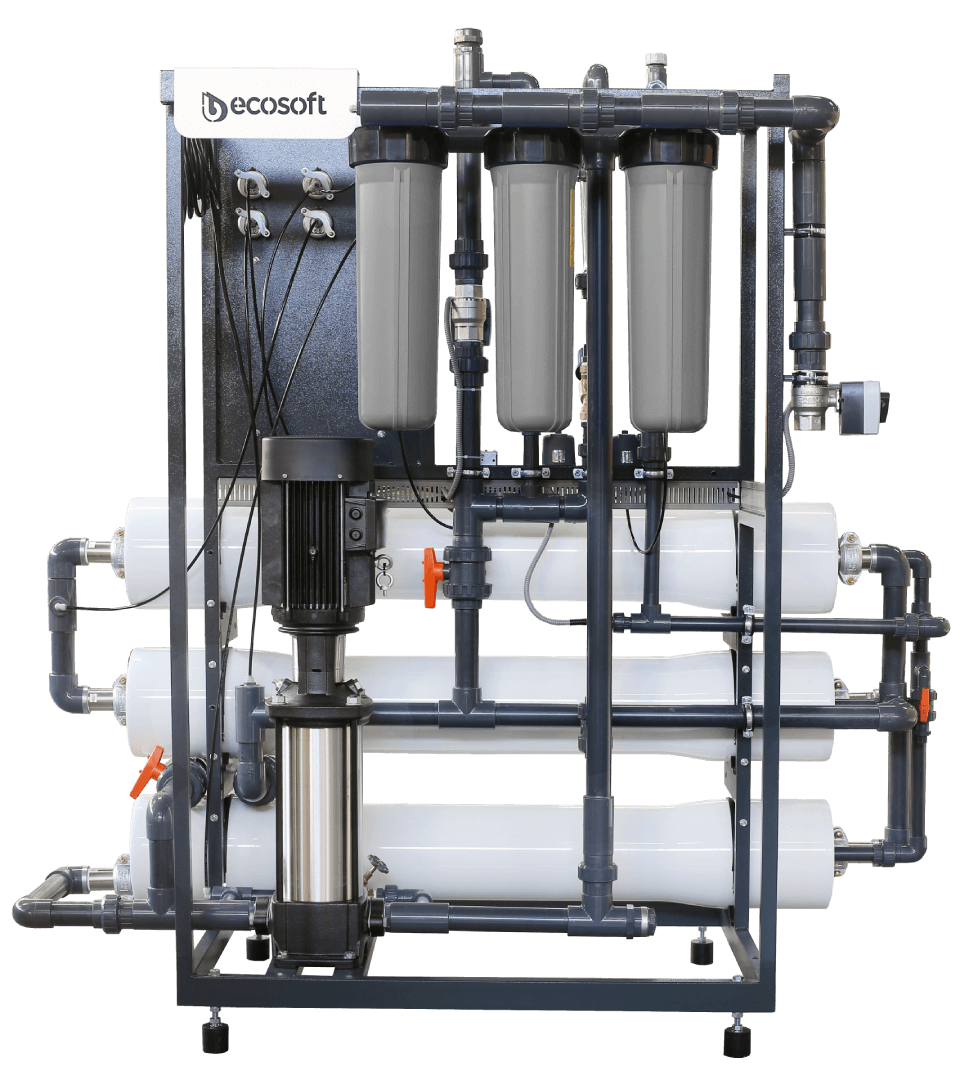

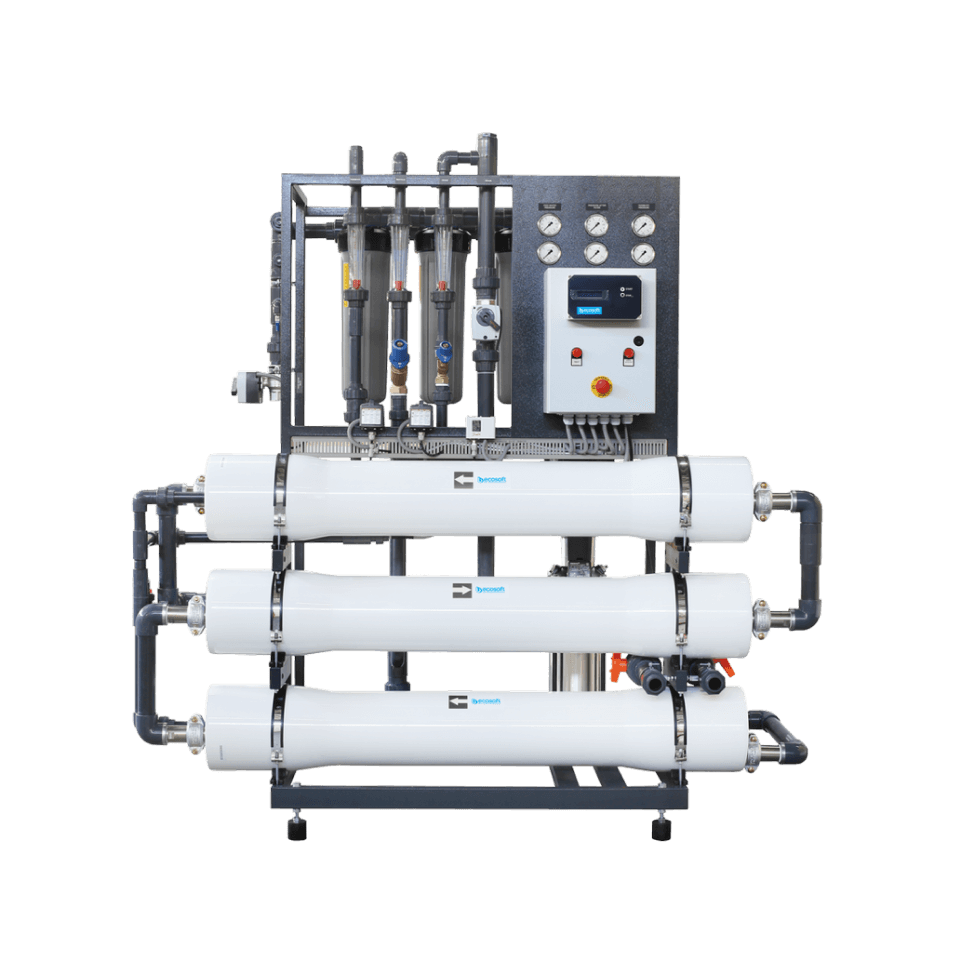

Ecosoft MO3 industrial reverse osmosis system is a turnkey solution for industrial water challenges, that includes pilot studies, engineering and manufacturing, commissioning and maintenance.

Ecosoft reverse osmosis systems are used in food and pharmaceutical industry, energy, chemical, semiconductor manufacturing, steam boilers and other industrial applications.

Permeate capacity

3-4

m³/h

Recovery

75

%

Maximum TDS

3000

mg/L

Influent flow demand (service)

4-6

m³/h

Operating pressure

8..12

bar

Power consumption

4

kW

Equipment

- Grundfos® CR 10-12 high pressure pump: 1 pcs

- 8040 membrane vessel: 3 pcs

- BB20 sediment prefilter: 3 pcs

- Motorized valves (feed water in, flush out): 2 pcs

- Balancing valves (concentrate reject, concentrate recycle): 2 pcs

- Electrical cabinet with Ecosoft controller: 1 set

- Piping, instrumentation, steel frame: 1 set

Options

- Filmtec™ XLE-440 / ECO PRO-440 or Ecosoft ELP-8040 membranes

- Dosing pump for antiscalant or other RO chemicals

- Permeate inlet for permeate membrane rinse

- Raw water blending line

Сonnections

- Influent water: 1½″

- Permeate: 1″

- Concentrate: 1½″

- CIP inlet: 1½″

- CIP return: 1½″

- CIP permeate: ½″

- Antiscalant dosing port: ½″

Technical data

- Permeate capacity¹: 3 m³/h

- Permeate recovery²: 75%

- Maximum TDS: 3000 mg/L

- Influent flow demand:

- 4…6 m³/h (service)

- 10 m³/h (rinse) - Operating pressure: 8…12 bar

- Maximum pressure: 14 bar

- Electrical requirements: 380...400 V, 50 Hz (3 ph)

- Electrical power: 4 kW

- Prefilter rating: 5 μm

¹ depends on feed water TDS, temperature, and permeate recovery

² for low scaling/fouling water

Feed water requirements

- TDS: 3000 mg/L

- hardness: 150 mg/L CaCO₃

- iron: 0.1 mg/L

- manganese: 0.05 mg/L

- hydrogen sulfide: none

- silicate: 20 mg/L

- residual chlorine: 0.1 mg/L

- SDI: 5

- chemical oxygen demand: 4 mg/L O₂

Product

Box

Image Size

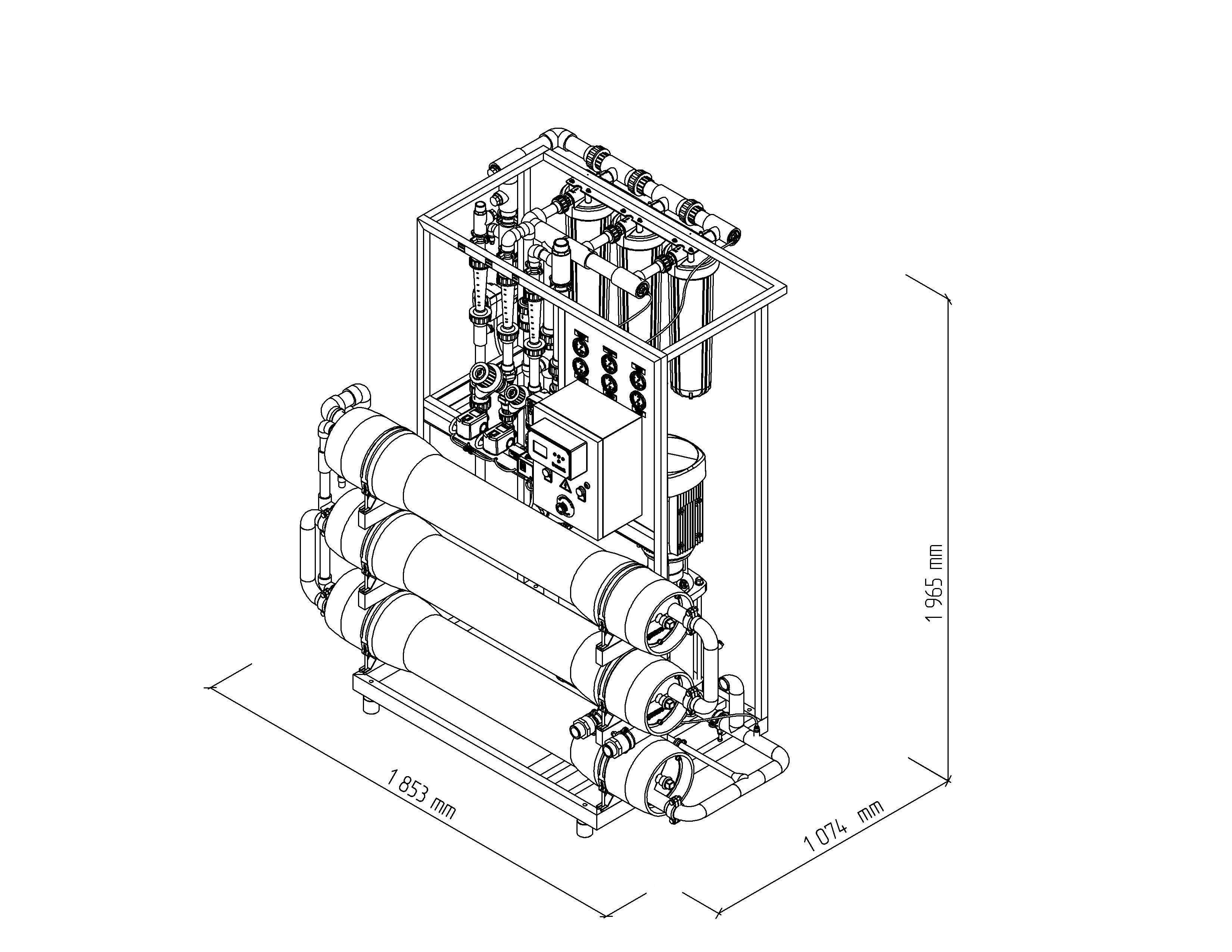

DIMENSIONS, H×W×D:

1965 × 1853 × 1074

mm

Filter weight

400

kg

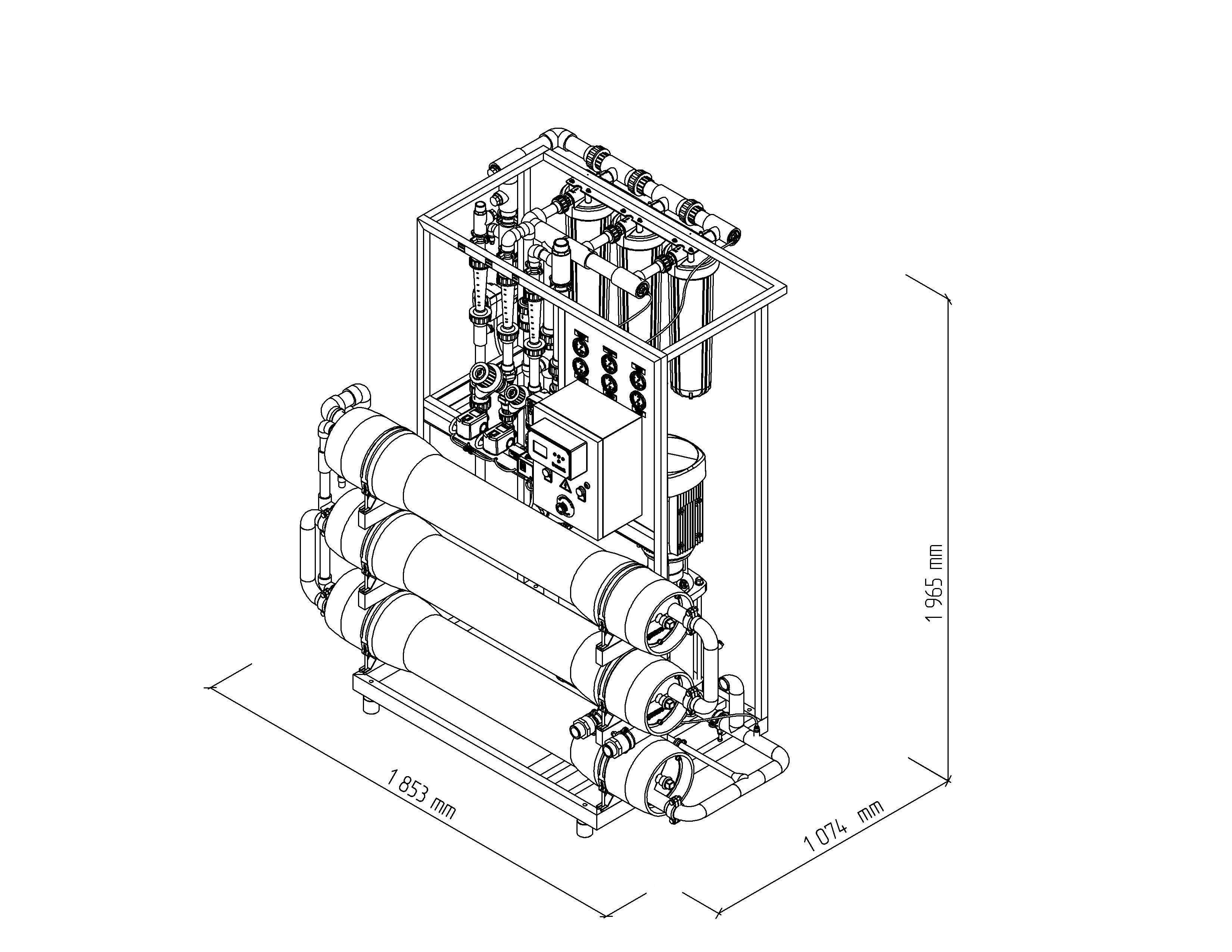

Image Box

Dimensions, H×W×D:

2276 × 2040 × 1250

mm

Filter weight

450

kg