Commercial reverse osmosis systems are the reliable turnkey solutions for various commercial and residential applications. Water bottling plants, steam boilers, garden centers, restaurants and many other types of businesses take advantage of their excellent performance and durability.

Flow capacity

500

L/h

Inlet water pressure

2..4

bar

Maximum TDS

3000

mg/L

Influent flow demand (service)

650–800

L/h

Operating pressure

8..12

bar

Power consumption

0.7

kW

Equipment

- Grundfos® CM 1-10 pump

- 300 psi membrane vessels

- BB20 sediment prefilter

- Electrical panel with Ecosoft controller

- Danfoss solenoid valves

- Piping, instrumentation

- Steel frame

- Carton crate

- PP melt blown sediment filter, 5 micron

Options

- Filmtec™ ХLE-4040 / LCLE-4040 or Ecosoft ELP-4040 membrane

- Dosing pump for antiscalant

- Versatile set for raw water blending (30...240 L/h) or permeate flushing

Connections:

- influent water: ½"

- permeate: ½"

- concentrate: ½"

- antiscalant dosing port: ½″

- permeate flushing input port: ½″

Specifications

- Permeate capacity*: 500 L/h

- Permeate recovery**: 75%

- Maximum TDS: 3000 mg/L

- Influent flow demand

- 650…800 L/h (service)

- 1500…2000 L/h (rinse) - Operation pressure: 8…12 bar

- Maximum pressure: 14 bar

- Electrical requirements: 230 V, 50 Hz (1 ph)

- Electrical power: 0.7 kW

- Prefilter rating: 5 μm

* depends on feed water TDS, temperature, and permeate recovery

** for low scaling/fouling water

Feed water requirements

- Influent water temperature: +5...+40 °С

- Residual chlorine, max: 0.1 mg/L

- Hardness: up to 3 meq/L (150 mg/L CaCO₃)

- Iron: up to 0.1 mg/L

- Manganese: up to 0.05 mg/L

- Silicate: up to 20 mg/L

- Chemical oxygen demand, max: 4.0 mg О₂/L

- Hydrogen sulfide: none

The limitations may be exceeded if using antiscalant, oxygen scavenger, or other RO chemical pretreatment.

OC5000 controller

The OC5000 controller is designed for automatic or manual control of reverse osmosis unit and provides:

- automatic switching on and off of the equipment upon signal;

- emergency shutdown of the equipment by signals from dry-running sensors, overpressure in the module;

- shutdown of equipment on the external STOP signal;

- hydraulic flushing of membranes;

- permanent quality control (electrical conductivity and temperature) of permeate.

Applications

- Steam boilers

- Heating and cooling circuits

- Breweries and beverage production

- Livestock and poultry farms

- Glazing factories

- Laundry and car wash

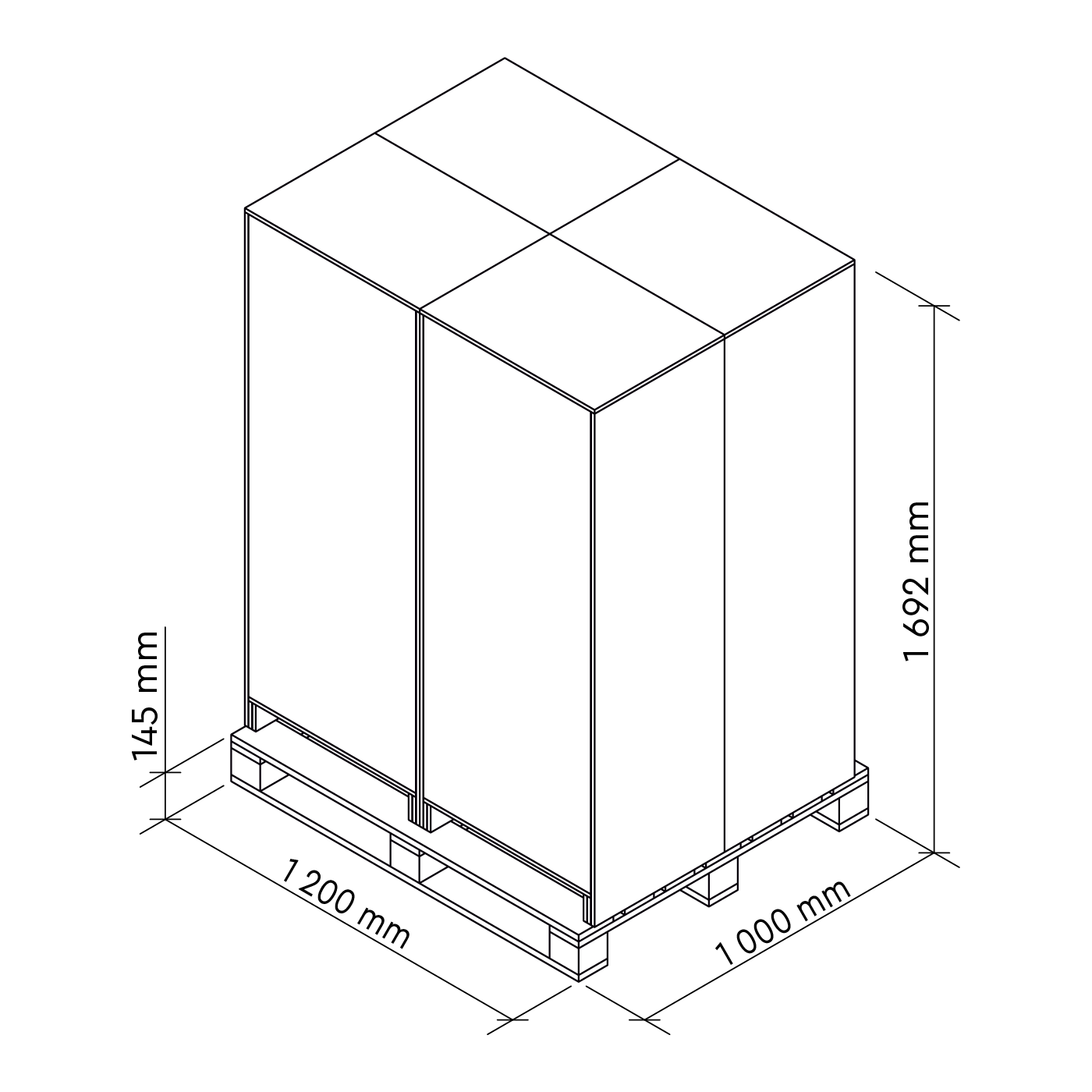

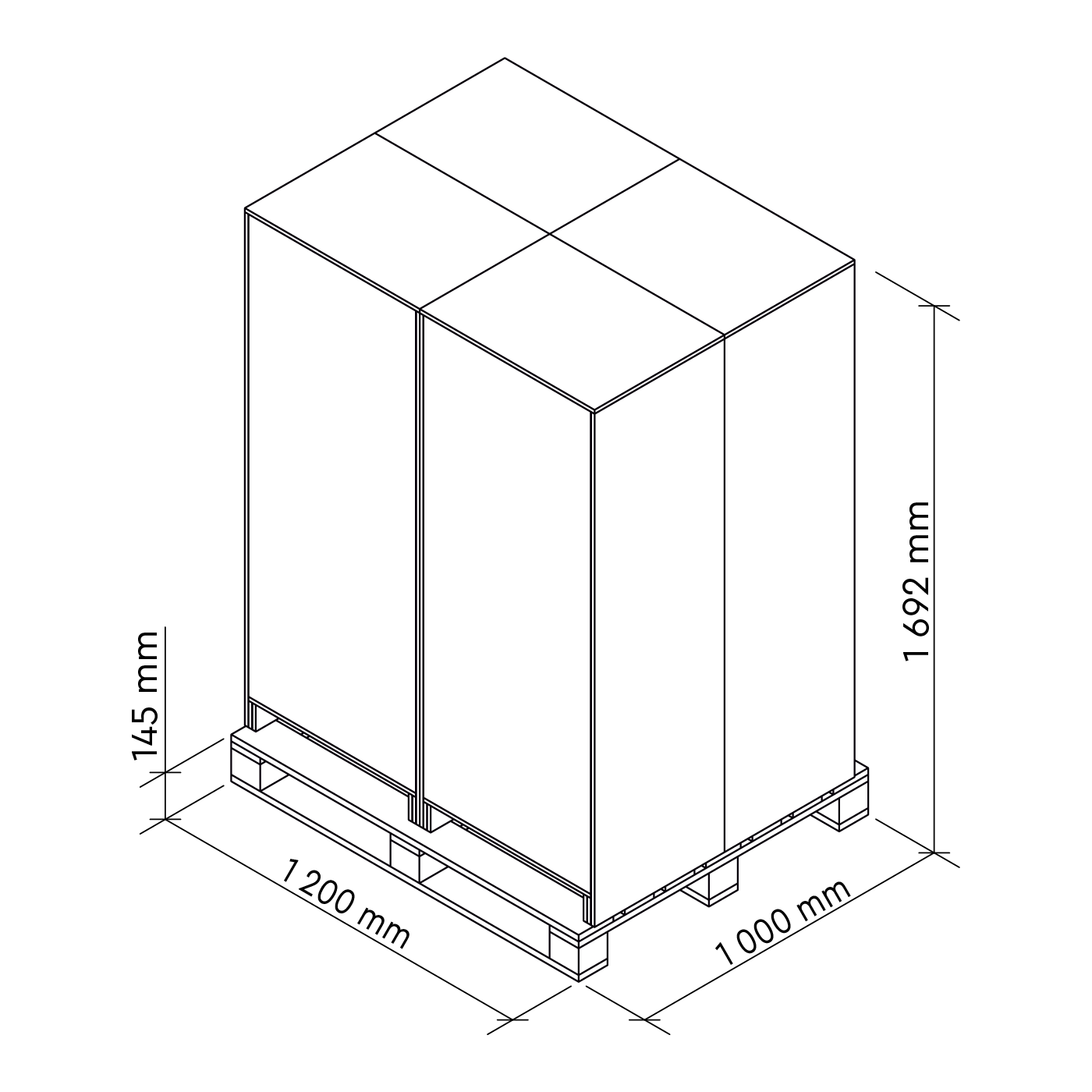

Product

Box

Palette

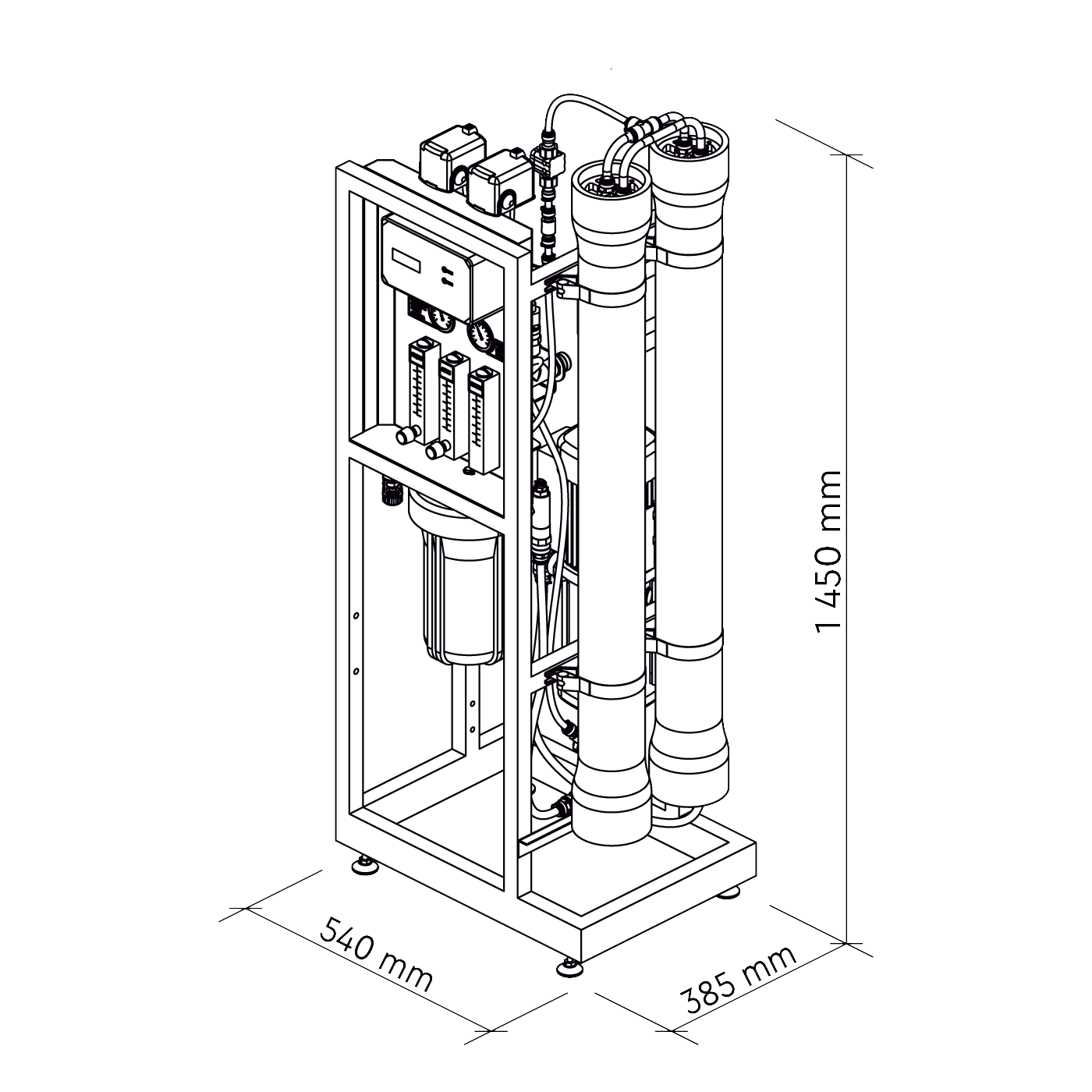

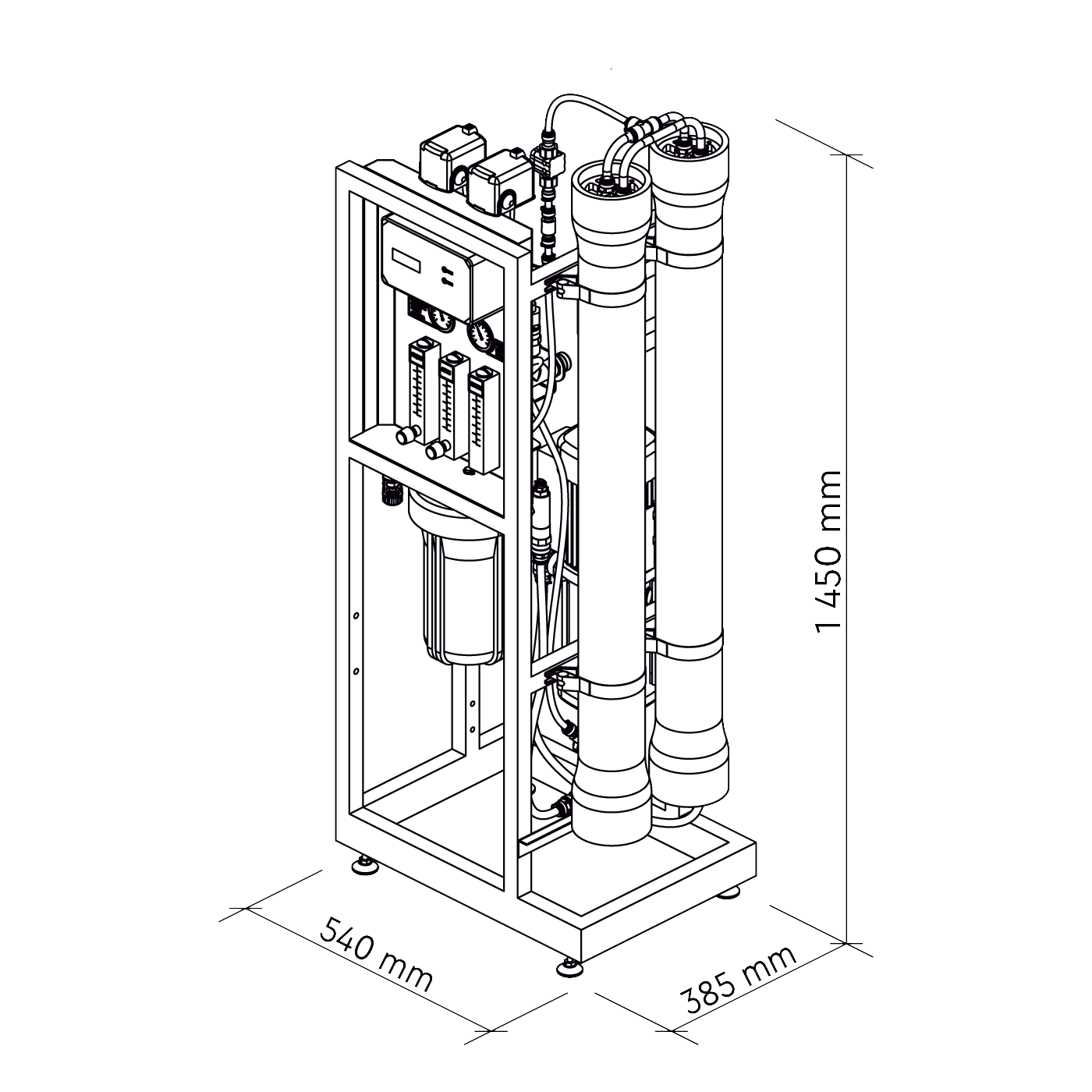

Image Size

DIMENSIONS, H×W×D:

1450×540×385

mm

Filter weight

60

kg

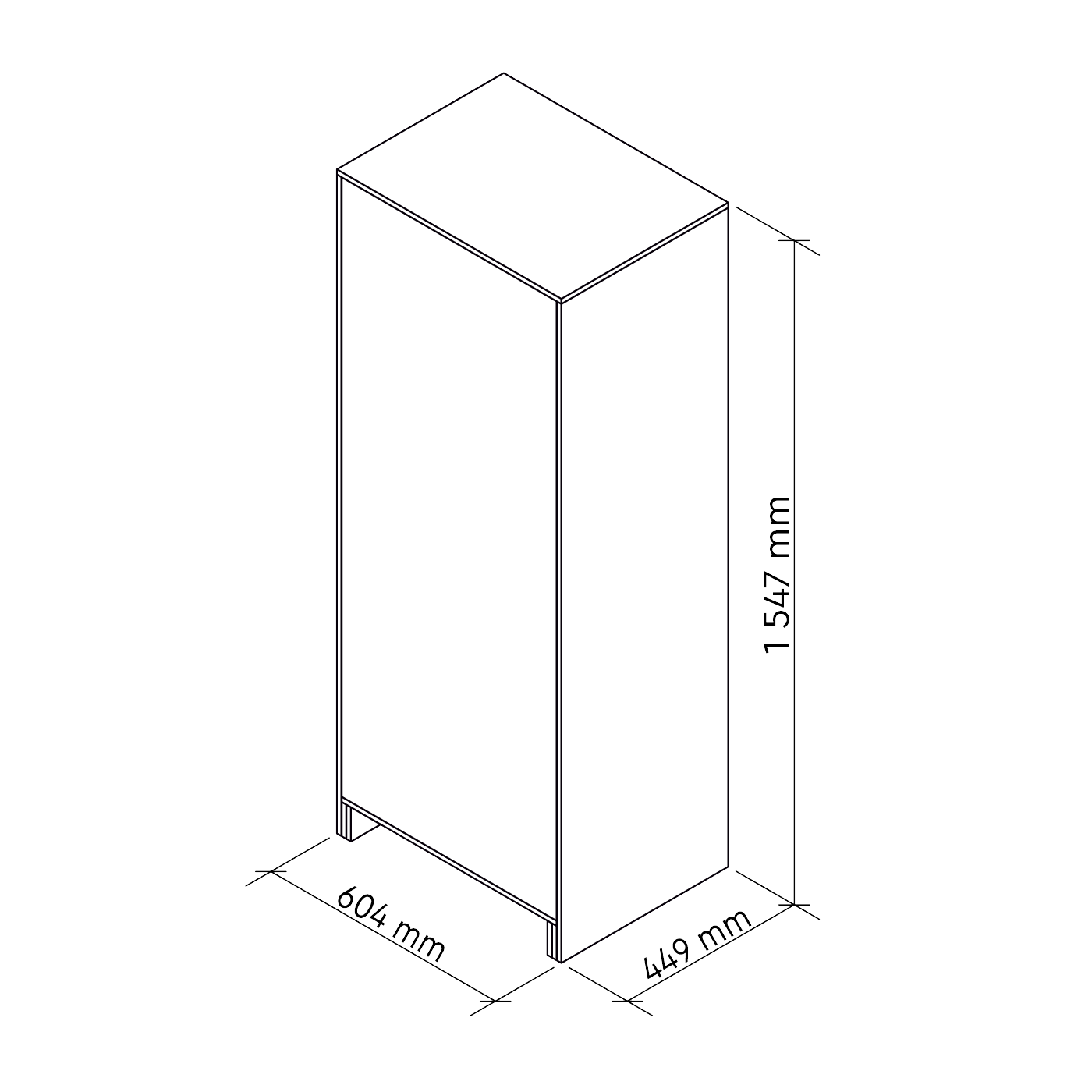

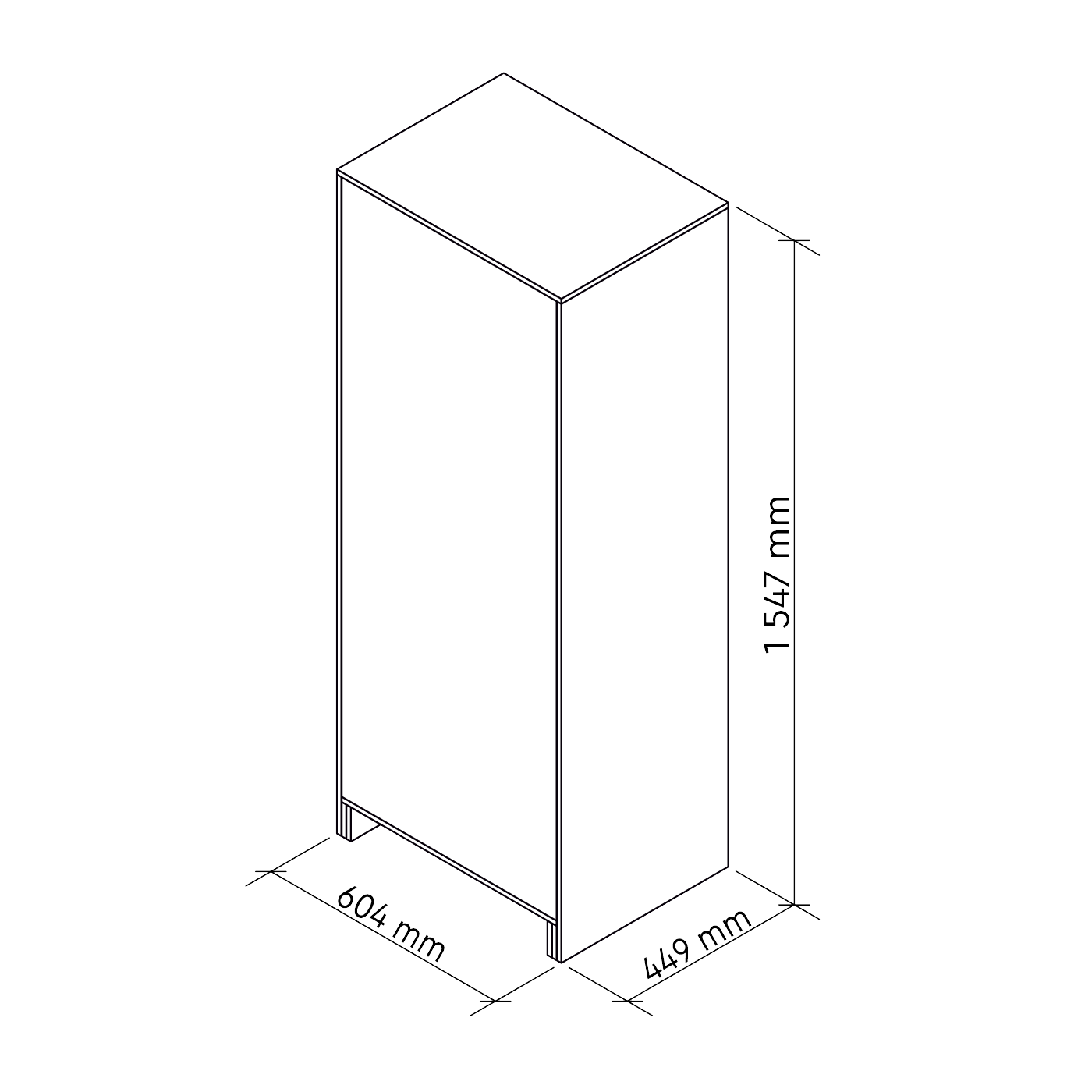

Image Box

Dimensions, H×W×D:

1547×604×449

mm

Filter weight

85

kg

Image Palette

Pieces on pallet

4

pcs

Weight on pallet

340

kg