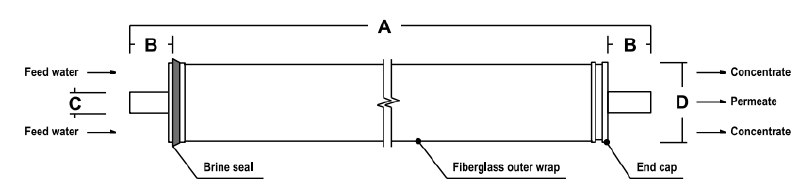

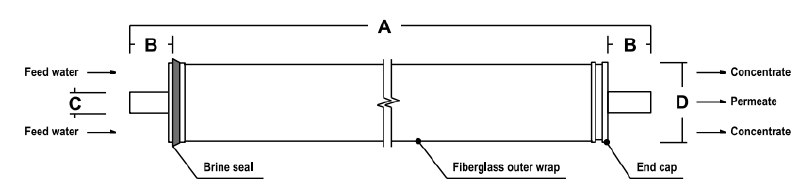

ELP-4040 membranes are spiral wound membrane elements for reverse osmosis systems. ELP-4040 are intended for purification of brackish water in low pressure systems. Large active surface area together with high rejection rates allows to use these membranes in variable pressure and flow conditions without deterioration of permeate quality.

Specifications

Membrane type: spiral-wound element with polyamide thin-film composite

- Active area: 8.1 m²

- Operating pressure: 10.3 bar

- Flow rate: 9.0* m³/day

- Stabilized salt rejection: 99.2 %

- Feed spacer thickness: 0.7 mm

* Permeate flow and salt (NaCl) rejection based on the following standard test conditions: 2 000 mg/L NaCl, 25 °C, 15% recovery. Flow rates for individual elements may vary but will be no more than 15% below the value shown.

Operating parameters

- Maximum operating water temperature: 45 °C

- Maximum operating pressure: 41 bar

- Maximum element pressure drop: 1.0 bar

- pH range, continuous operation: 2...11

- pH range, short-term cleaning: 2...12

- Maximum Feed Silt Density Index (SDI): 5

- Free chlorine tolerance: < 0.1 mg/L

Maintenance

Before initiating system start-up procedures, membrane pretreatment, loading of the membrane elements, instrument calibration and other system checks should be completed. Please refer to the product manual for more information.

During startup, it is recommended to gradually transfer the system from standstill to operational state as follows:

- The inlet water pressure should be raised gradually within 30-60 seconds.

- The operating flow rate should be achieved gradually over a period of 15-20 seconds.

- Permeate obtained during the first hour of operation is discarded.

Important information

- After starting, wetting always keep the elements wet

- To prevent biofouling during long breaks in work it is recommended to immerse the membrane elements in preservative solutions.

- The maximum pressure drop is 2.1 bar.